Coppercoat antifouling…or even conventional antifouling…short term, should work at least to some extent to prevent marine growth on a sailboat hull, right? After 6 or 7 weeks, there should be no barnacles or build up of marine growth, no matter what kind of nutrient rich water your boat is sitting in, and no matter how little movement the boat makes, right? Well, we have been in the water for 7 weeks now…this should give us some idea if our Coppercoat application has failed or succeeded. 7 Years will tell us even more!

Patrick was feeling confident that although we strayed from the Coppercoat application instructions, that the hull would be in good shape, free from hard growth. I was a little concerned that we might have a failed Coppercoat application story for you. At the very least we would be able to tell you why the Coppercoat failed. Everything you read about Coppercoat says do NOT stray at all from the instructions. We certainly DID stray from the instructions, mostly out of necessity to get the results we knew were required to make the Coppercoat application successful in the end. Patrick isn’t one to follow directions blindly just because his wife tells him to…he uses sense and knowledge when he strays.

So despite being in very brown mucky water here in Richards Bay, South Africa, with bull sharks, crocodiles and hippos not too far away, Patrick decided that before we sail this boat around the Cape of Good Hope starting this weekend, he should take a look, or at least a feel of the bottom of our sailboat to make sure it’s not encrusted with barnacles or other serious marine growth. This which would make for a a slow and potentially dangerous rounding, not to mention, put a lot of strain on the engine if we had to motor. While he was down under the boat, he’d give it a wipe. Better to have crocodiles, hippos, a sinus infection, and a not so friendly bull shark, than a hull encrusted with barnacles for an already risky passage like this one!

We were both nervous as he got in to the water to clean the bottom of Brick House. I kept thinking, what if the Coppercoat has failed!?! What a nightmare that would be! We would probably have to haul her out and choose another kind of antifouling paint to put on her hull. And what if a Bull shark visits Patrick…will he know who the boss is? I think Patrick’s main worry though, was the sinus infection.

As he slipped in to the water that was nearly as warm as the hot African air, I prayed, please…do NOT be a failed Coppercoat application. SV Britican’s hull was growing serious barnacles in less time that this. And this water grows barnacles in a week on many boats here.

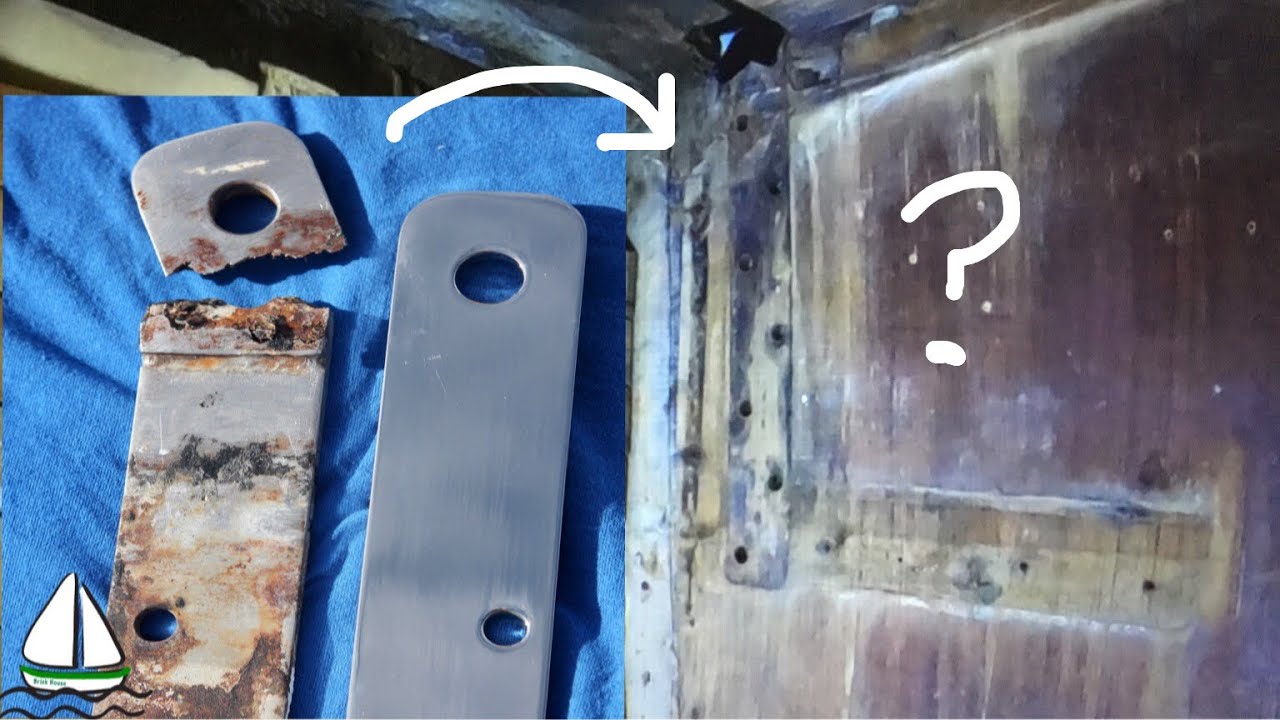

So in he went. He did have scrapers, and wire brushes at the ready…just in case of bad news, ready for the typical disappointment that bottom paints usually present, even in this early stage.

After 15 or 20 minutes at the end of the Seabreathe hookah unit, he surfaced for the report. I was ready to hand him the scraper, and watch him dissapear back under the water for round 2 of many, per usual.

He handed me the sponge, and jumped out of the water with a giant smile on his face! First time ever…he didn’t need these harsh tools…the soft sponge was all he needed!

Here is his report for weeks 7, word for word:

“We have been sitting in this very nutrient rich estuary water for 7 weeks now. Part of the prep for departing in a few days for East London, then onto Cape Town, was to go into this mucky estuary water, with 4 inches of visibility, and give the hull a wipe with a large, flat, soft sponge. I worked more by feel. What little I could see and what I could feel, Coppercoat is appearing to be working as it should. There were 3 little barnacles on the hull, at the tight junction where the drive shaft enters the hull and I wasn’t able to really apply the Coppercoat very well. Actually I was happy to see and feel those barnacles as it shows what could have happened if the Coppercoat was a failure on the rest of the hull. The wipe with the sponge took a fraction of the time it would have taken to clean traditional antifouling free of sediments“.

What a relief that we possibly have a Coppercoat success, as opposed to the Coppercoat failure that I was a bit nervous about. The 3 barnacles on the area that he had a more difficult time treating, was a good comparison of what could have been a universal problem. He described to me under later questioning that from what he could see from 4 inches away, the hull looked to be in various shades of blue and green which indicates a successful Coppercoat application to me!

We could not be happier, to see that we are at least off to a good start. Perhaps the extra sanding will shorten its life span…but if it works for 2 years we will be thrilled. If it works for 5 or 10, we will be ecstatic!

Be sure to subscribe here to get updates on our Coppercoat Application Failure or Success as time goes by. We promise not to give a Coppercoat review every 6 weeks 😉 We are just excited to report all is well so far. Please feel free to write to us and ask us how it’s going if we forget to report the results over time!

Here is the Original Application Video in case you haven’t seen it yet. Only time will tell how the Coppercoat works longterm.

How we strayed from the Coppercoat Instructions